Industrial wearable technology is a rapidly growing field that possesses the remarkable potential to revolutionize numerous industries. By equipping workers with wearable devices, this technology can gather valuable data, offer real-time feedback, and even control machinery. As a result, it becomes a catalyst for enhancing safety, productivity, and efficiency in the workplace.

How Does Industrial Wearable Technology Work?

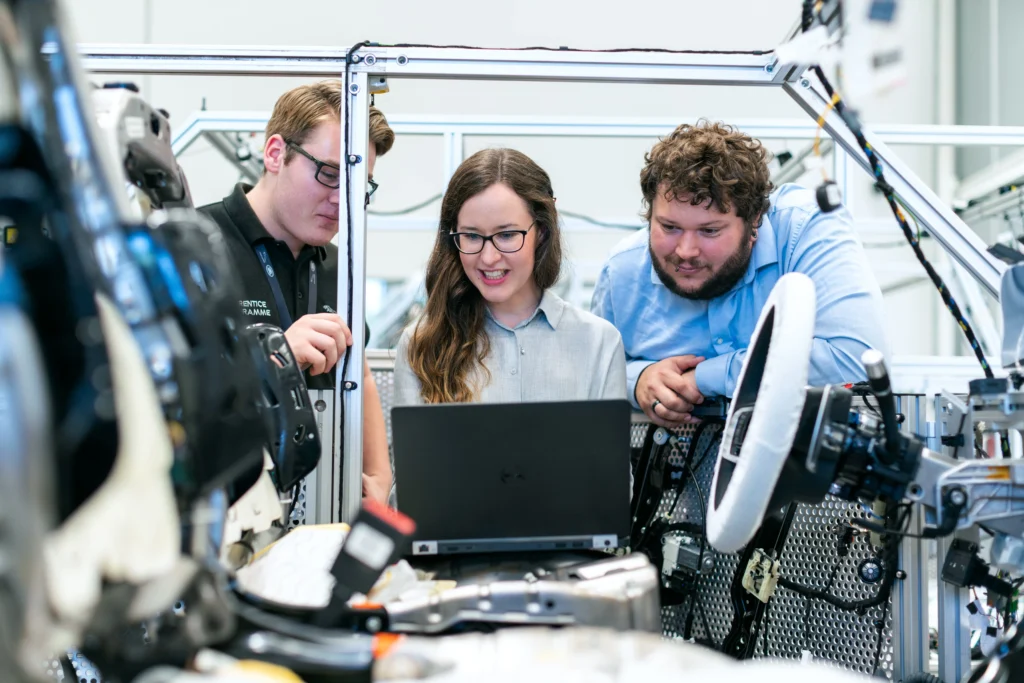

The functionality of industrial wearable technology typically involves two main components: a wearable device, such as a smartwatch or a smart helmet, and a cloud-based platform. The wearable device collects data regarding the worker’s location, movements, and heart rate, which is then transmitted to the cloud platform. Subsequently, the cloud platform analyzes the data and generates insights that can be utilized to improve safety, productivity, and efficiency.

The Revolutionary Impact of Industrial Wearable Technology

Industrial wearable technology is ushering in a revolutionary transformation across various industries. Let’s delve into some illustrative examples:

Enhancing Safety

Wearable devices are instrumental in monitoring worker movements and location, leading to accident prevention. For instance, GE implemented wearable devices to track the activities and positions of their employees within their factories. By leveraging this data, GE effectively identified high-risk areas and implemented measures to avert potential accidents. This proactive approach resulted in a remarkable 20% reduction in accidents within GE’s factories.

Boosting Productivity

Real-time feedback provided by wearable devices empowers workers to enhance their performance, accuracy, and efficiency. A notable example is UPS, which employs wearable devices to track the location of their drivers and cargo. Leveraging this data, UPS optimizes delivery routes, ensuring timely arrival of shipments. As a consequence, UPS experienced a notable 10% improvement in delivery efficiency.

Amplifying Efficiency

Wearable devices play a crucial role in gathering data related to production processes, facilitating identification of areas for improvement. Trimble, for instance, employs wearable devices to monitor the location of workers at construction sites. This data is utilized to ensure workers’ safety by directing them to designated areas and preventing accidents. As a result, Trimble successfully reduced the number of accidents on their construction sites by an impressive 15%.

Facilitating Communication

Wearable devices offer seamless communication channels between workers and supervisors, promoting effective coordination, task allocation, and problem reporting. In a practical example, a construction company utilized wearable devices to establish swift communication with workers at a construction site. This efficient communication framework facilitated task coordination and expedited the provision of worker assistance. Consequently, the company completed the construction project on time and within the allocated budget.

Empowering Training

Wearable devices serve as a valuable tool for providing training to workers, delivering video tutorials, and offering real-time performance feedback. In 2021, a manufacturing company harnessed the potential of wearable devices to deliver training to their workforce. This expedited training process resulted in a remarkable 15% increase in the company’s production output.

Industries Benefiting from Industrial Wearable Technology

The adoption of industrial wearable technology has already made significant strides across various industries, including:

- Manufacturing: In the manufacturing sector, wearable devices are utilized to enhance safety, productivity, and efficiency. For instance, GE effectively deploys wearable devices to track worker movements and location within their factories, thereby mitigating the risk of accidents.

- Logistics: In the realm of logistics, wearable devices are employed to track shipments and improve overall operational efficiency. UPS effectively leverages wearable devices to monitor the location of their drivers and cargo, resulting in optimized delivery routes and punctual shipments.

- Construction: Wearable devices play a pivotal role in the construction industry, ensuring worker safety and augmenting productivity. Trimble, for instance, harnesses wearable devices to monitor the location of workers on construction sites, proactively preventing accidents and promoting safe work practices.

- Healthcare: The healthcare sector embraces wearable devices for patient monitoring and remote care provision. The Mayo Clinic, for instance, utilizes wearable devices to monitor patients with chronic illnesses. This data aids in tracking patients’ conditions and facilitates timely intervention when required.

- Mining: In the mining industry, wearable devices are deployed to enhance safety and productivity. BHP Billiton, for example, effectively employs wearable devices to track the location of workers within their mines, safeguarding workers’ well-being and minimizing the occurrence of accidents.

- Oil and Gas: The oil and gas industry relies on wearable devices to maximize safety and operational efficiency. Shell, a prominent industry player, effectively utilizes wearable devices to track the location of workers on oil rigs, thereby ensuring their safety and preventing accidents.

The Promising Future of Industrial Wearable Technology

The potential of industrial wearable technology continues to evolve and inspire further innovation. As the technology progresses, we can anticipate even more remarkable applications across diverse industries. Here are a few insights into the future of industrial wearable technology:

- Advancements in Wearable Devices: Future wearable devices will incorporate increasingly sophisticated features, enabling the collection and analysis of more extensive data. This enhanced functionality will provide unprecedented insights into worker safety, productivity, and efficiency.

- Enhanced Affordability: The cost of wearable devices will witness a downward trajectory, rendering them more accessible and affordable for businesses. This affordability factor will accelerate the widespread adoption of industrial wearable technology.

- Growing Acceptance among Workers: As wearable devices become more commonplace, workers will become more accustomed to their usage. Familiarity breeds acceptance, thereby mitigating the current challenges associated with worker adoption.

In conclusion, industrial wearable technology holds immense promise, despite the challenges it faces. With ongoing advancements and decreasing costs, we can expect to witness widespread adoption of this transformative technology. The future of industrial wearable technology is characterized by boundless potential, which will drive innovation and reshape industries for years to come.